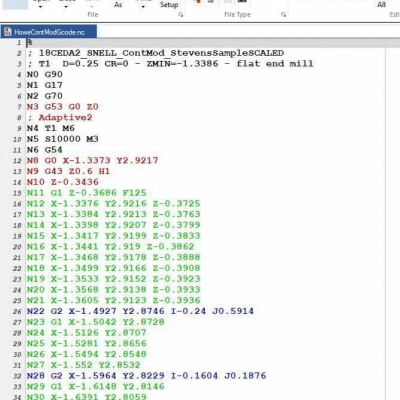

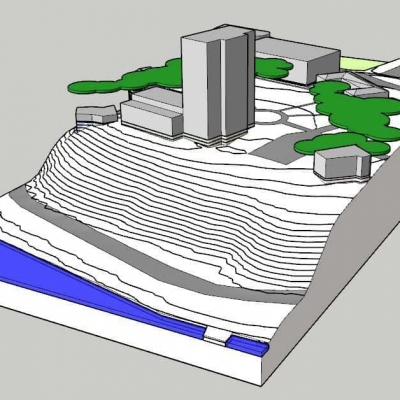

TOOLS: DRAWING, MODELING, GRAPHICS

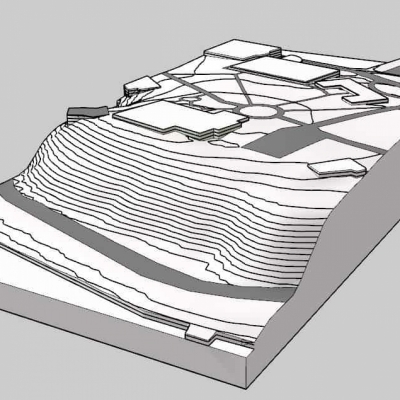

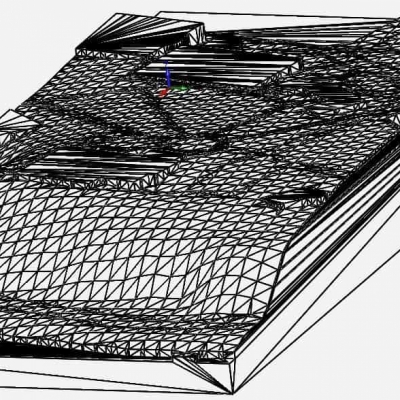

My work in design, research, and teaching is centered around the conversation between the computer model and the physical thing it is modeling. Whether the model locus is spatial, structural, thermal, site, graphic or some other chosen ecosystem, I have learned that the tools and platforms will constantly change, so they cannot be the focus. First, you have to constantly look for overlaps in how the software is structured and strive to accept and enjoy the fact that half of the process is always learning new things, then embrace that the other half is troubleshooting. Most importantly though you cannot get mesmerized. Just as the natural environment is fundamental to the built, i.e. the built needs the natural but not vice versa, the model is a tool serving the built. I love the tools, but the physical is what counts.

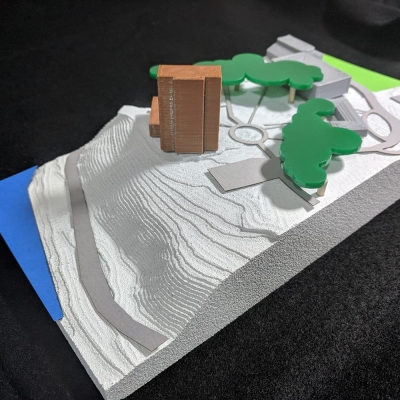

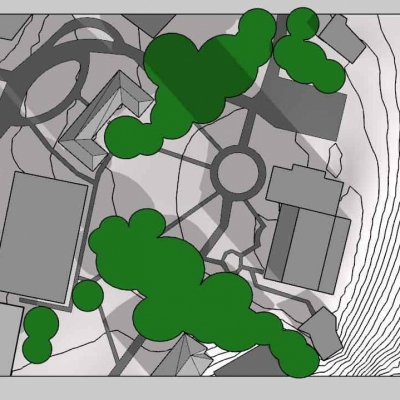

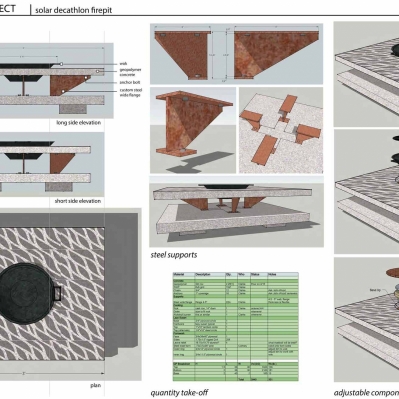

FIXING CONCRETE: URBAN EDEN PROJECT

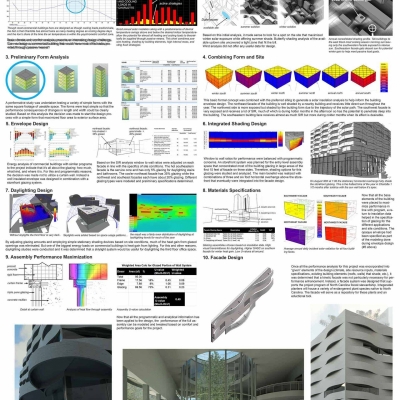

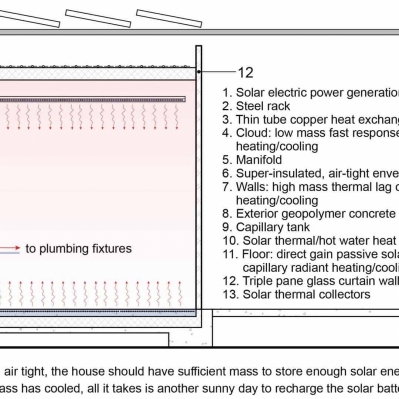

Over the past 10 years as climate change has continued to rear its progressively uglier head, my focus has turned more toward its mitigation as a design challenge. In terms of the built environment, concrete is center stage. On the one hand, it is responsible for a huge percentage of our collective carbon footprint, on the other it has great potential to save energy as part of an intelligently conceived building envelope. Concrete is, after all, a traditional material with thousands of years of history. It is hygroscopic and massive like the lion’s share of the systems I had been studying for years. While I was a graduate student at UNC Charlotte, we designed and built a project that I consider a step in the direction of “fixing concrete”. We applied research being done on campus to use a new kind of concrete, geopolymer cement concrete, that represented a massive reduction in carbon footprint in a high performance envelope of our own design. The project was UNCC’s entry in the 2013 Solar Decathlon which required it be a small, completely solar-powered house. We conceived it as an urban infill project for Charlotte and wanted to create a building that claimed its own private outdoors. We did this by essentially combining indoor and outdoor rooms into a single living environment. To read my more extensive architectural description, go here.

FIXING CONCRETE: THE “PASSICHANICAL” WALL SYSTEM

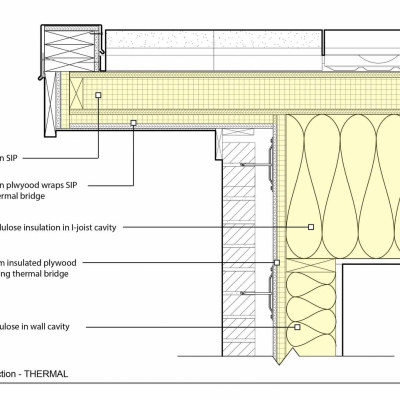

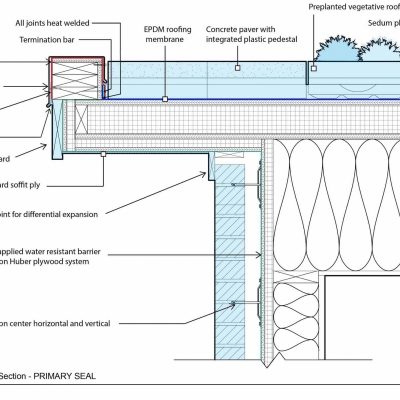

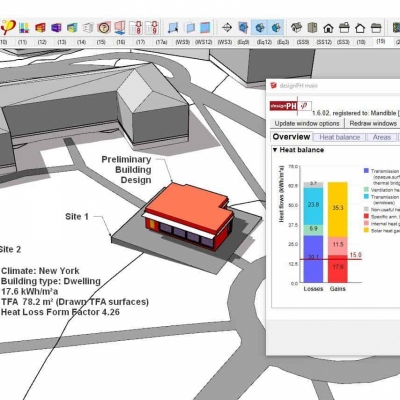

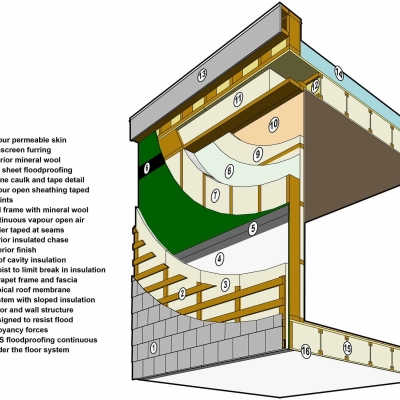

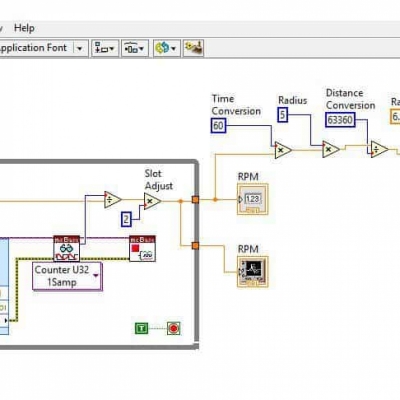

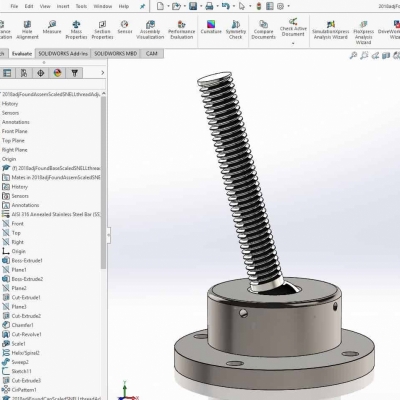

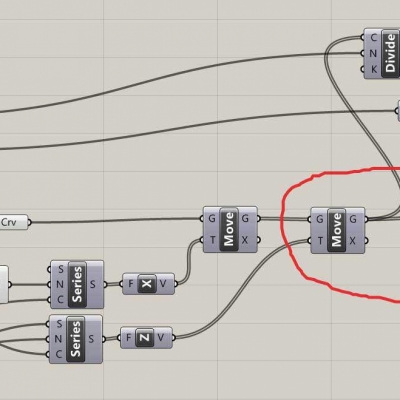

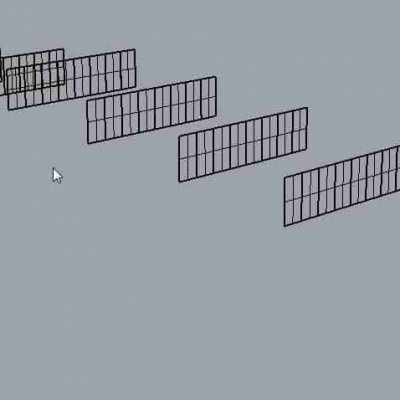

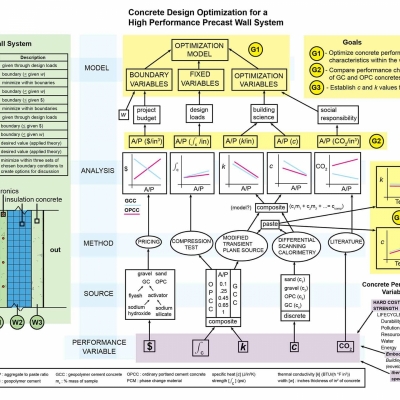

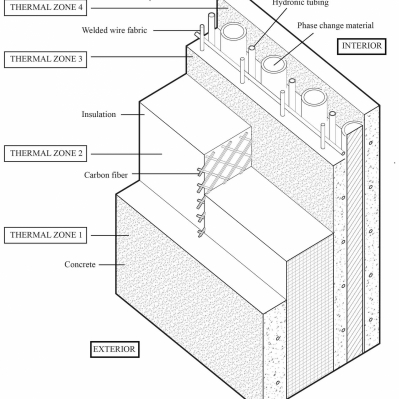

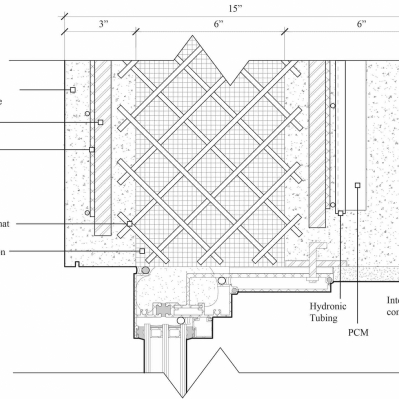

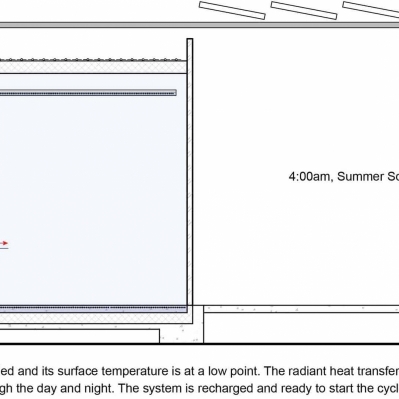

Passive first, then active. That’s my design philosophy. Passive design requires an understanding of the science of how specific climatic variables interact with building materials and assemblies. In buildings, passive happens in the zone of the envelope and so I’ve come to see envelope design as paramount. Recently, I’ve been working with Thomas Gentry and Brett Tempest to develop a high performance wall system that blurs the line between building envelope and mechanical system. I’m calling it “passichanical” somewhat tongue and cheek, but maybe that will stick. Here’s a brief slighty technical synopsis of the design:

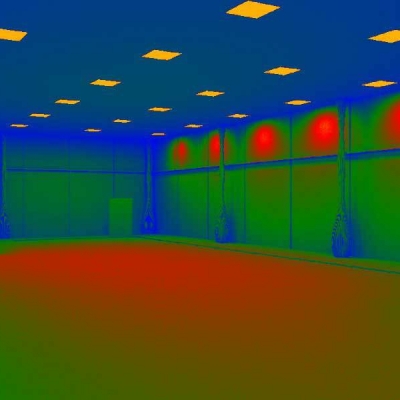

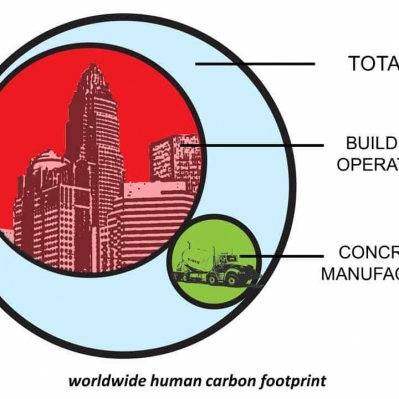

Building envelopes save energy by reducing the work required by mechanical systems to maintain interior comfort. They can accomplish this in at least three basic ways: 1) resisting the flow of heat with insulation; 2) storing heat with mass; and 3) regulating solar heat inputs to maximize or minimize gains through glazing and shading strategies. The current state of the art in the US focuses primarily on #1 for residential construction and on #3 for commercial construction, therefore considerably reducing the potential efficiency of standard building envelopes. When mass is incorporated in envelopes it is usually not configured to take advantage of thermal characteristics. In addition, as we’ve said, the ubiquitous mass material in use, portland cement concrete, requires huge primary energy usage to produce and consequently is responsible for approximately 7% of worldwide carbon emissions.

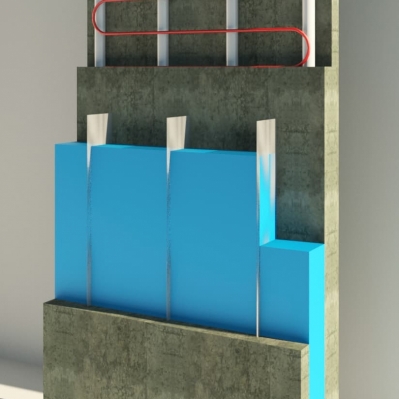

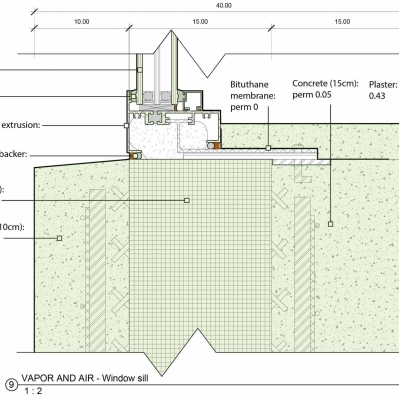

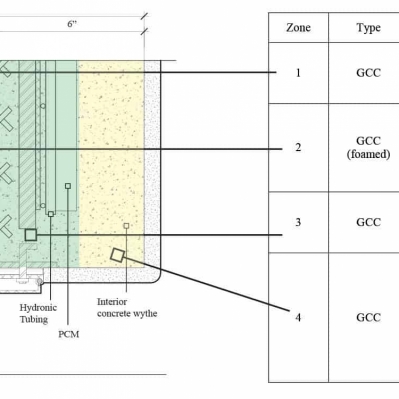

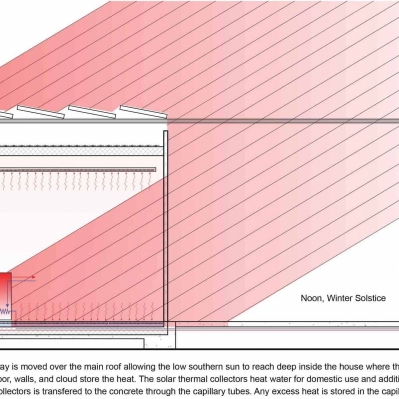

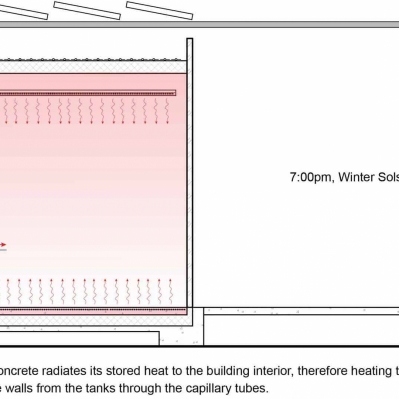

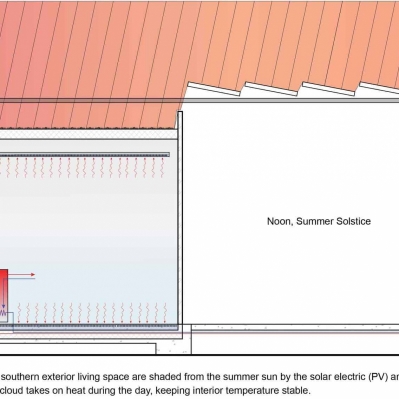

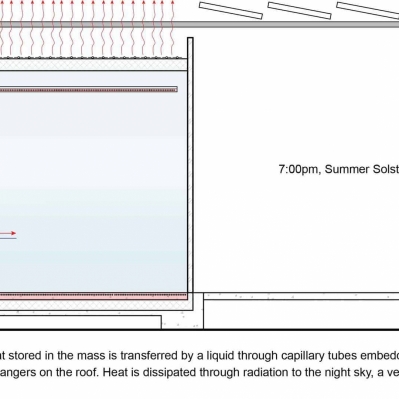

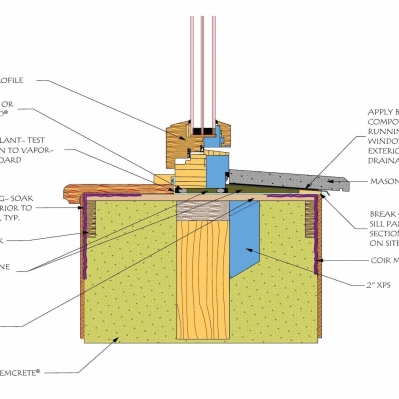

To address these deficiencies in current building envelope design, a wall system has been developed and is currently being studied at UNC Charlotte that consists of an optimized, engineered combination of innovative technologies creating a dynamic building envelope : 1) a geopolymer cement concrete (GCC) that drastically reduces the primary energy required to produce concrete; 2) a thermo-active building system (TABS) that utilizes hydronics, increased mass surface area, and roof mounted heat exchangers to deliver low-energy heat transfer in and out of the wall; 3) a carbon fiber epoxy composite that creates a structural connection between interior and exterior concrete wythes without thermal bridging or compromising hydronic thermal exchange; 4) an approach to macro-encapsulated phase change material (PCM) application that eliminates the partial phase change phenomenon common with PCMs; and 5) a unique approach to concrete mix design that optimizes for thermal performance through calculated attenuation of paste to aggregate ratios based on desired thermal response . These innovations in combination with existing continuously insulated, thermal bridge free precast concrete technology produce a revolutionary wall system that maximizes performance in all three categories for envelope energy savings: 1) insulation levels are not limited by cavity depths as in framed construction; 2) mass is configured inside insulation to take full advantage of thermal storage with volume and mix design easily adjustable to meet climate and site specific high performance requirements; and 3) the interior concrete wythe becomes a multi-layer passively augmented component of the mechanical system allowing for nuanced control (input or removal based on season) of solar and other heat sources.

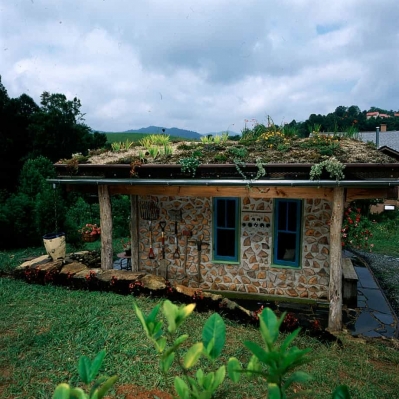

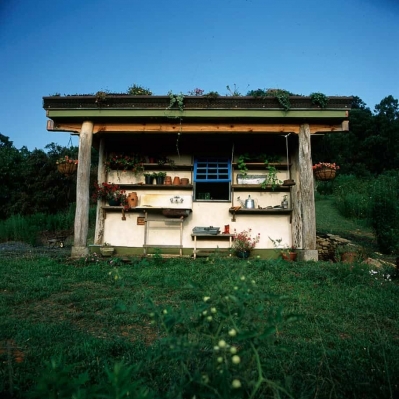

SITE-HARVESTED AND WASTE MATERIALS: “BUILDING GREEN” COTTAGE

There is a movement in the US to rekindle traditional building systems. The concept is that these approaches are less environmentally destructive while creating comfortable, efficient, beautiful spaces. To the extent which this is true, the success of indigenous building systems lies in the fact that they were developed in a specific cultural and climatic context. For example, in hot arid climates with diurnal temperature swings above and below desired interior temperatures, thick earthen walls can act as a form of dynamic insulation to create very comfortable spaces. However, transplant this same system to a wet, cold climate and you essentially have a car without an engine as the passive mechanism which drives the building system isn’t present. The question is can we access the considerable archive of building knowledge represented by indigenous systems and apply them to our contemporary context? This project was conceived to answer that question by applying site-made, local, and recycled materials and passive systems appropriately based on building science principles to create a tiny, flexible, efficient, and beautiful fully functional living space. Different building methods were compared based on performance in relation to a specific microclimate. For example, earthen materials (cob and clay-slip straw) were used on the south face of the building to take advantage of thermal mass to collect solar heat in the winter while straw bales where used on the north face because of their high thermal resistance. The project was conceived as a teaching tool and was designed and built to be documented as a book.

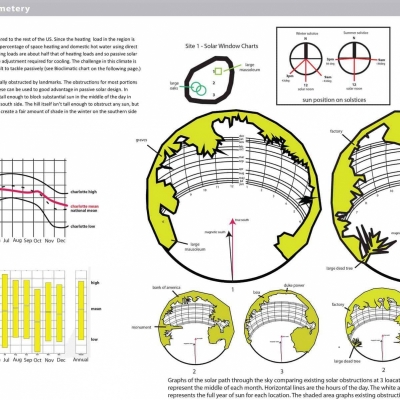

MASS-PRODUCED HYGROSCOPIC ENVELOPES: THE NAUHAUS

Traditional systems are great, but, let’s face it, times have changed. Our buildings have a more complex job these days as they are asked to provide a very stable interior comfort zone complete with running water and wireless internet. Also, mass production has lowered costs. If you don’t believe me go out and price a thatched roof compared to a high quality standing seam metal roof. And when it comes to financial and environmental impact, the materials themselves are only a small part of the story. It’s the operation of the building (heating, cooling, and plug loads) that is responsible for most of the resources a building uses through its life. Still, we don’t want to throw the baby out with the bathwater. Can we maintain the core wisdom of indigenous systems, which in my estimation is low-embodied energy materials and passive design tailored to microclimates, while tapping the benefits of mass-production and advanced building science? The Nauhaus Project was conceived as an attempt to do just that. The project was designed to the Passivhaus standard, probably the most rigorous building energy standard in the world which requires very careful design of an airtight thermal-bridge free envelope that allows a lower impact mechanical system and provides superior indoor environmental quality. The wall system, however, was intended to emulate many traditional systems in that it utilized mass in a hygroscopic assembly. The material chosen, Hemcrete, was made from a waste material (shiv) but engineered, packaged, and sold as a mass-produced product allowing for quality control and accurate cost estimation. Site-made materials were used when they fit the performance goals. Interior floors and mass walls are compressed earth block made on site and the interior is plastered with a variety of earthen plasters. Many innovative systems were incorporated combining simple passive technologies with high performance mechanicals. The design minimized interior square footage with extensive use of outdoor rooms creating an incredibly comfortable living space that can be heated by the body heat of ten people on the coldest day of the winter in fairly cold climate (Asheville, NC).