SITE-HARVESTED AND WASTE MATERIALS

Maximizing the lifecycle performance of a building envelope is a balance of lowering the embodied energy of production, installation, and deconstruction while maximizing operational performance. I started my career focusing on low-embodied energy materials and systems. This realm is often called “natural building”, a marketing term that I have never understood. These methodologies generally have a long history connected to a specific climate and culture and as such have much to teach us about efficient resource use.

It is interesting to me that most indigenous building systems share a similar approach to water. Generally the approach is to redirect most of the liquid water away from the building while allowing the wall volume to be hygroscopic, meaning that it can take on and give off water vapor in response to humidity changes. In contrast to the typical industrial approach which is to attempt to lock water out with “super materials” such as impermeable sheet materials and joint sealants, hygroscopic systems are more forgiving since they have limited potential for trapping water in the building volume. This can lead to a more durable product with many traditional buildings lasting hundreds and even thousands of years. However, in my experience it is difficult to adapt these systems to our contemporary context for a number of reasons including scalability, quality control, performance quantification, and the expense of what essentially are custom-made materials in an economy driven by mass production.

As a result, I am interested in the R&D of materials for applications in industrial systems that maintain the climate specific performance gestalt of their indigenous forebears. For basic info on a project in which I was involved that marries state of the art contemporary building science with a mass produced hygroscopic wall system go here.

FIXING CONCRETE: GEOPOLYMER CEMENT

Portland cement concrete (OPCC) is responsible for about 7% of our worldwide human carbon footprint. Partly that’s because it’s the 2nd most used material worldwide (water is the first) but it also has very high embodied energy due to the fact that portland cement is produced essentially by burning rocks!… more specifically limestone.

There are a number of alternatives in development and one of the most exciting is geopolymer cement concrete (GCC). Geopolymers are a class of material consisting of a mineral (geo) chain of molecules (polymer) that are linked with covalent bonds. Alumina silicate-based geopolymers when combined with certain reagents and water can produce a geopolymer cement appropriate as a binder in concrete mixes. Though the resulting GCC product has a similar range of structural and durability characteristics to OPCC, the raw materials are minimally processed and/or industrial byproducts resulting in a drastic reduction in CO2 emissions of up to 70% to 90% in comparison to OPCC, depending on which journal article you cite . It seems then that GCCs have the potential to deliver the positive high performance characteristics of conventional concrete without the negative environmental costs.

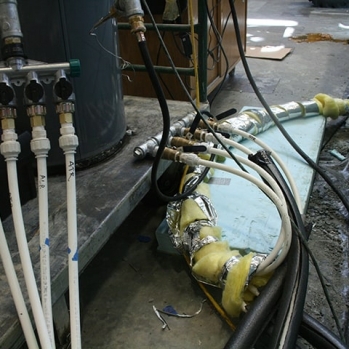

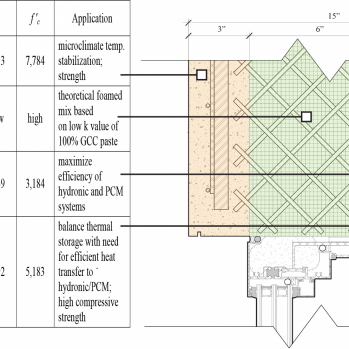

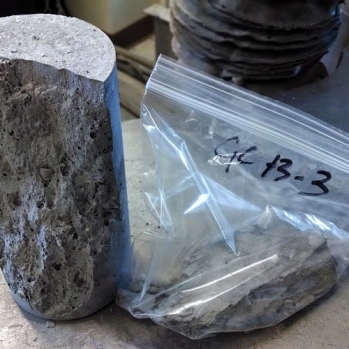

I was part of a team at UNC Charlotte studying and developing GCC mixes specifically for use in high performance building envelopes. In a partnership with Metromont, a local pre-caster, we produced the first insulated building envelope in the world using GCC as part of UNCC’s 2013 Solar Decathlon entry, proving that the technology can be produced today using existing industrial infrastructure.

FIXING CONCRETE: THERMAL OPTIMIZATION

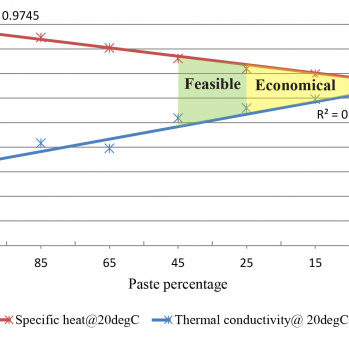

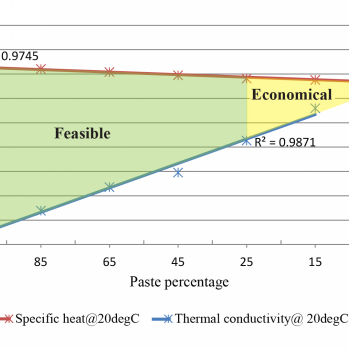

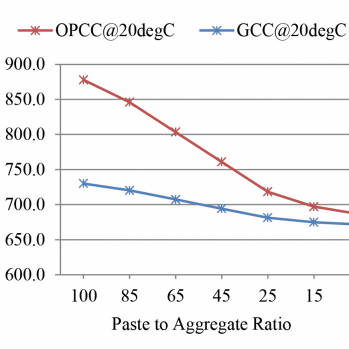

The malleability of concrete’s performance characteristics is one of its inherent strengths. Through adjusting a variety of variables including paste to aggregate ratios, water content, aggregate composition, paste characteristics, and a number of potential admixtures, a variety of physical characteristics can be controlled. Typically concrete used in buildings is divided into two categories: structural and architectural (sometimes called “finish”), with nuanced and exacting mix designs well established through a long development history to create a wide performance spectrum within each category.

However, concrete has an equally long history as a thermal material utilized both as thermal storage and to reduce or enhance thermal movement through building envelopes, the ancient Roman Baths at Ostia and the Anasazi Pueblo in present day New Mexico being just two examples. Similarly, long before the advent of the contemporary concept of insulation, concrete and other mass materials have constituted the full volume of the building envelopes of perhaps the vast majority of the world’s buildings, providing whatever resistance to heat flow there was that allowed a different temperature to be maintained indoors than existed outdoors. Yet concrete mix designs focusing on thermal performance in building envelopes are essentially non-existent.

My feeling is that investigating the efficacy of such a mix design strategy is an important component in the search for more energy efficient building envelopes that utilize concrete and in the general movement to lower the embodied energy and consequent carbon footprint of concrete in the built environment. The central rationale is that in a lifecycle analysis the lion’s share of a typical building’s environmental impact is through its operation . Therefore, improving building operational performance will have the most significant effect on its energy and carbon impact. It has been well established that the key to maximizing operational performance is to reduce heating, cooling, lighting and plug loads first before considering improving HVAC applications or employing renewable energy systems. Which load category has the largest effect on building performance is determined by many variables, but the thermal properties of the building envelope consistently play a significant role. Add to this the ubiquity with which concrete is employed as a major component of the built environment in its current incarnation, and it seems clear that there is a compelling rationale for investigating thermal optimization strategies for concrete mix designs in building envelopes.

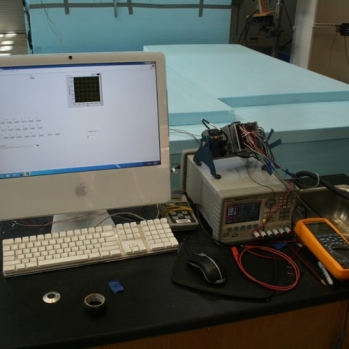

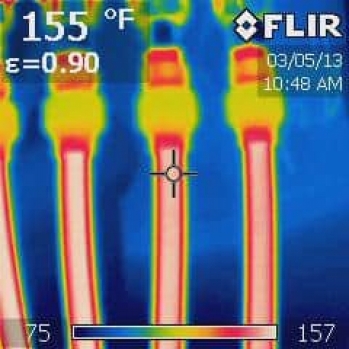

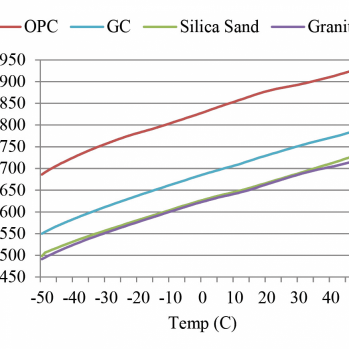

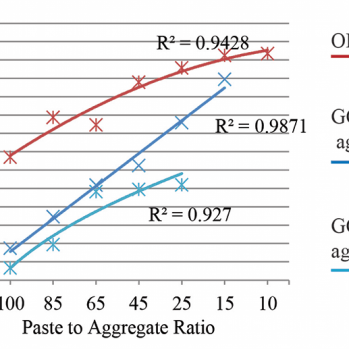

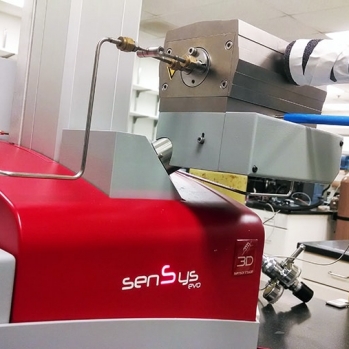

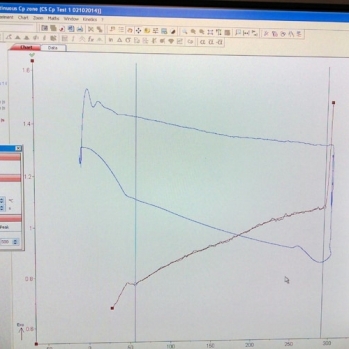

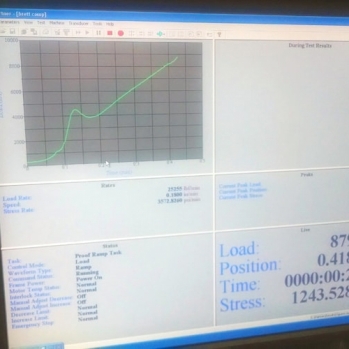

I have completed an initial study of the thermal characteristics (specific heat capacity and thermal conductivity) of concrete mixes of differing paste to aggregate ratios, comparing OPCC to GCC mixes. The results along with an incipient methodology for optimizing concrete mix designs for thermal characteristics were published in the Journal of Architectural Engineering.